Kontraktor Fire Protection

PT Adiwarna Anugerah Abadi Tbk

Didirikan pada tahun 2007 dan telah menjadi perusahaan kontraktor fire protection yang berkembang pesat dengan fokus pada bisnis proteksi kebakaran.

PT Adiwarna Anugerah Abadi Tbk mengkhususkan diri pada solusi proteksi kebakaran yang lengkap. Kami fokus pada proteksi kebakaran dengan bahaya tinggi dan industri yang memiliki risiko khusus seperti: pabrik minyak & gas, pusat data, perbankan, pembangkit listrik, petrokimia, dan pabrik industri.

Ruang Lingkup Pekerjaan

Desain & Rekayasa

Desain & Rekayasa yang sesuai dengan Desain Standar Internasional & Nasional, solusi yang dirancang khusus.

Persediaan

Produk Kelas Dunia dengan Persetujuan Internasional seperti Terdaftar di UL, Disetujui FM, Lloyd’s Register, DNV, ABS.

Instalasi

Tim Teknisi yang berpengalaman dan standar kerja pemasangan yang tinggi serta jadwal proyek yang tepat waktu.

Pengujian & Komisioning

Tim teknisi yang terlatih dan berpengalaman untuk melakukan pengujian & komisioning.

Layanan & Pemeliharaan

Tim teknisi yang terlatih dan berpengalaman untuk melakukan layanan & pemeliharaan.

Desain & Rekayasa yang sesuai dengan Desain Standar Internasional & Nasional, solusi yang dirancang khusus.

Produk Kelas Dunia dengan Persetujuan Internasional seperti Terdaftar di UL, Disetujui FM, Lloyd’s Register, DNV, ABS.

Tim Teknisi yang berpengalaman dan standar kerja pemasangan yang tinggi serta jadwal proyek yang tepat waktu.

Tim teknisi yang terlatih dan berpengalaman untuk melakukan pengujian & komisioning.

Tim teknisi yang terlatih dan berpengalaman untuk melakukan layanan & pemeliharaan.

Jelajahi berita terbaru, laporan terkini, dan wawasan menarik. Temukan informasi yang Anda butuhkan disini.

- Informasi

- Berita Terbaru

- 23 Juni 2025

Kebakaran merupakan salah satu risiko bencana yang paling merusak, tidak hanya mengancam...

- Informasi

- Berita Terbaru

- 23 Mei 2025

Jakarta, Mei 2025 – PT Adiwarna Anugerah Abadi Tbk (NAIK), perusahaan penyedia...

- Informasi

- Berita Terbaru

- 19 Mei 2025

Medical Checkup PT Adiwarna: Investasi Kesehatan Karyawan & Produktivitas PT Adiwarna Anugerah...

- Informasi

- Berita Terbaru

- 24 April 2025

PT Adiwarna Anugerah Abadi Tbk (NAIK) Gelar RUPST Tahunan 2024: Pengesahan Laporan...

- Informasi

- Berita Terbaru

- 10 Desember 2024

Jakarta, November 2024 – Kabar gembira menghampiri pasar modal Indonesia pada bulan...

- Informasi

- Berita Terbaru

- 20 Agustus 2024

Tujuan Kunjungan ke PT Adiwarna Sistem Pemadam Kebakaran Inergen menjadi fokus utama...

- Informasi

- Artikel

- 13 Oktober 2025

Dalam desain bangunan modern, keselamatan jiwa bergantung pada efektivitas sistem...

- Informasi

- Artikel

- 12 Oktober 2025

Deteksi kebakaran dini adalah kunci keselamatan jiwa. Di garis depan...

- Informasi

- Artikel

- 10 Oktober 2025

Generasi Baru Deteksi Asap yang Lebih Cerdas dan Stabil Di...

- Informasi

- Artikel

- 8 Oktober 2025

🔥 Perbedaan Fire Pump UL Listed dan Fire Pump Sesuai...

- Informasi

- Artikel

- 6 Oktober 2025

Garda Terdepan untuk Kesehatan Jangka Panjang Sistem Anda Air yang...

- Informasi

- Artikel

- 5 Oktober 2025

Penjaga Senyap untuk Sistem Proteksi Kebakaran Anda Dalam setiap sistem...

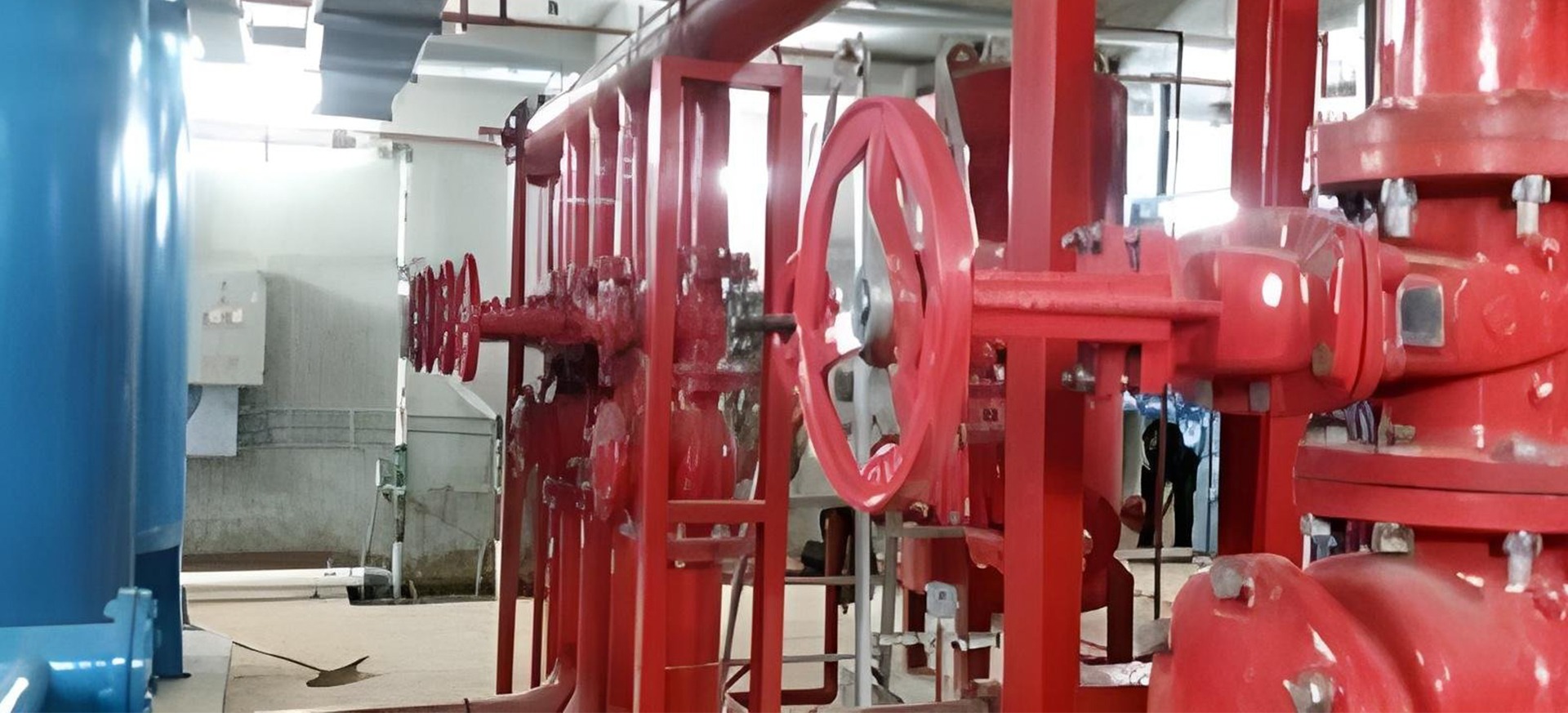

- Fire Suppression & Fire Fighting Package

Adiwarna telah memasang Paket Fire Suppression & Fire...

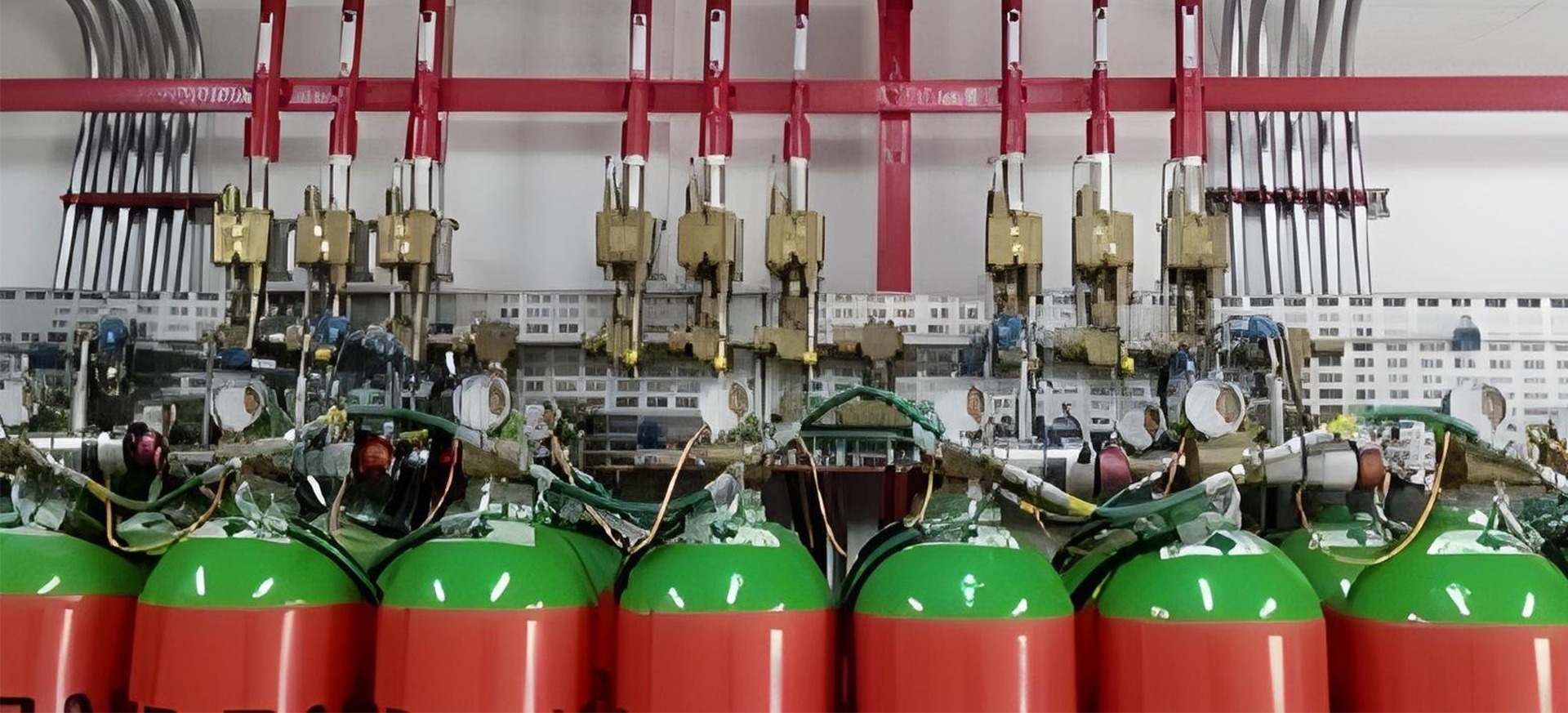

- Sistem Pemadam Kebakaran Inergen

Adiwarna telah memasang sistem pemadam kebakaran inergen untuk...

- Sistem Pemadam Kebakaran Inergen

Adiwarna telah memasang sistem pemadam kebakaran inergen untuk...

- Sistem Pemadam Kebakaran FM200

Adiwarna telah memasang sistem pemadam kebakaran FM200 untuk...

- Paket Proteksi Kebakaran

Adiwarna telah memasang paket proteksi kebakaran untuk PT...

- Fire Alarm & Clean Agent System CPBL

Adiwarna telah memasang Fire Alarm & Clean Agent...

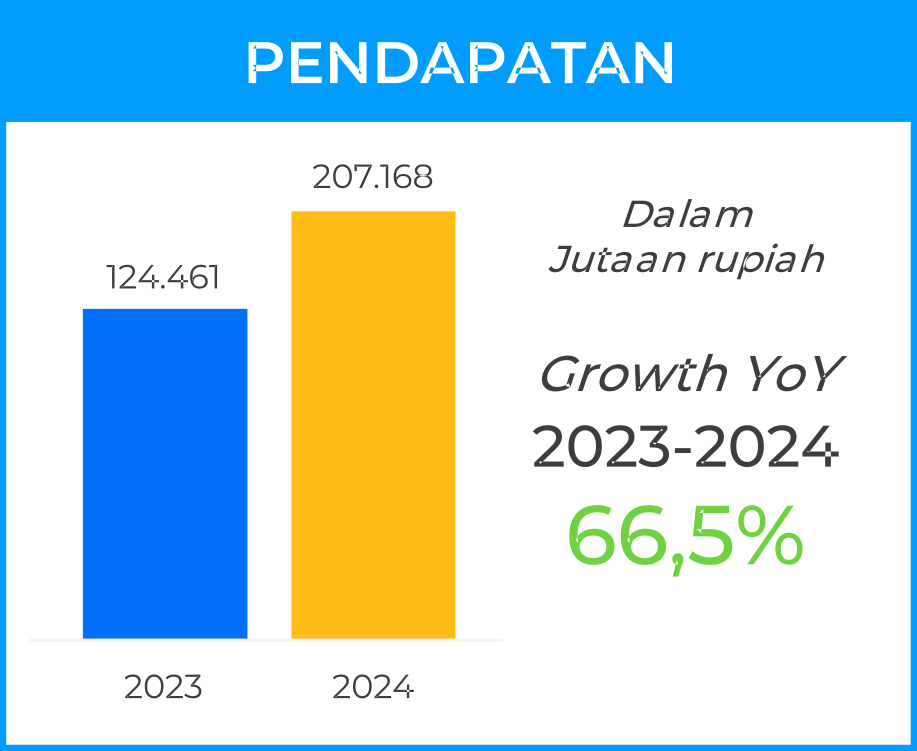

Pencapaian signifikan Perseroan berupa pendapatan sebesar Rp 207.168 miliar sepanjang tahun 2024. Kesuksesan ini menunjukkan komitmen perusahaan dalam mempertahankan pertumbuhan bisnis yang berkelanjutan di tengah persaingan industri yang semakin ketat.

Dalam laporan keuangan terakhir, Perseroan mencatatkan pertumbuhan pendapatan sebesar Rp207.168 miliar naik 66,45% dari tahun sebelumnya, yang mencerminkan efisiensi operasional dan peningkatan permintaan akan layanan perusahaan.

Laporan Laba Rugi

| Laporan Laba Rugi | 2024 | 2023 |

|---|---|---|

| Pendapatan | 207.168 | 124.461 |

| Beban Pokok Pendapatan | (146.005) | (86.153) |

| Laba Kotor | 61.162 | 38.307 |

| Laba Sebelum Pajak | 34.073 | 14.653 |

| Beban Pajak | (3.171) | (1.465) |

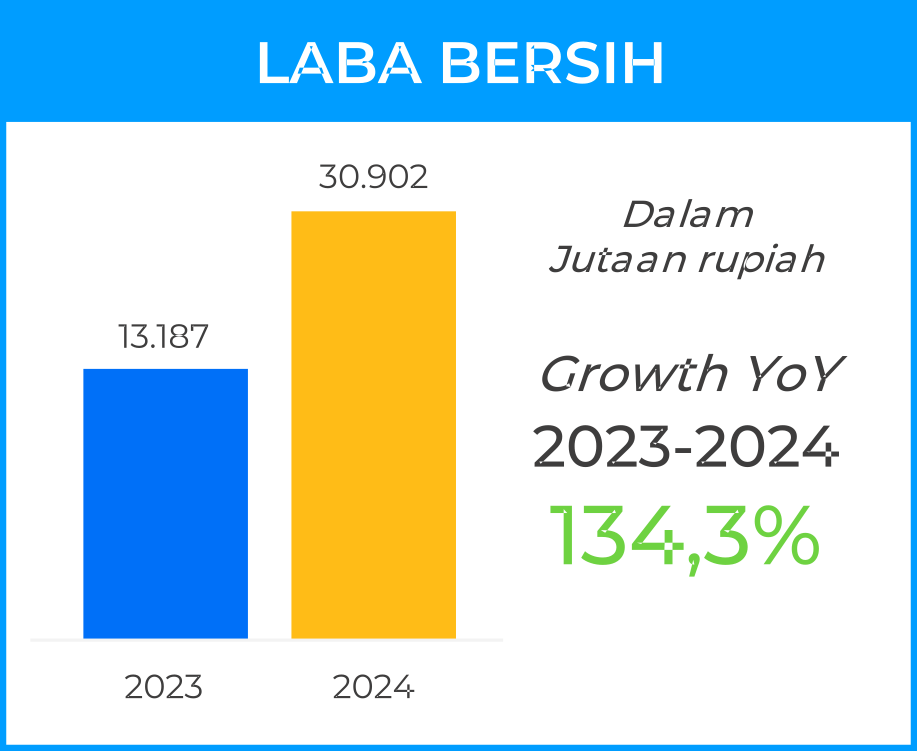

| Laba Periode Berjalan | 30.901 | 13.187 |

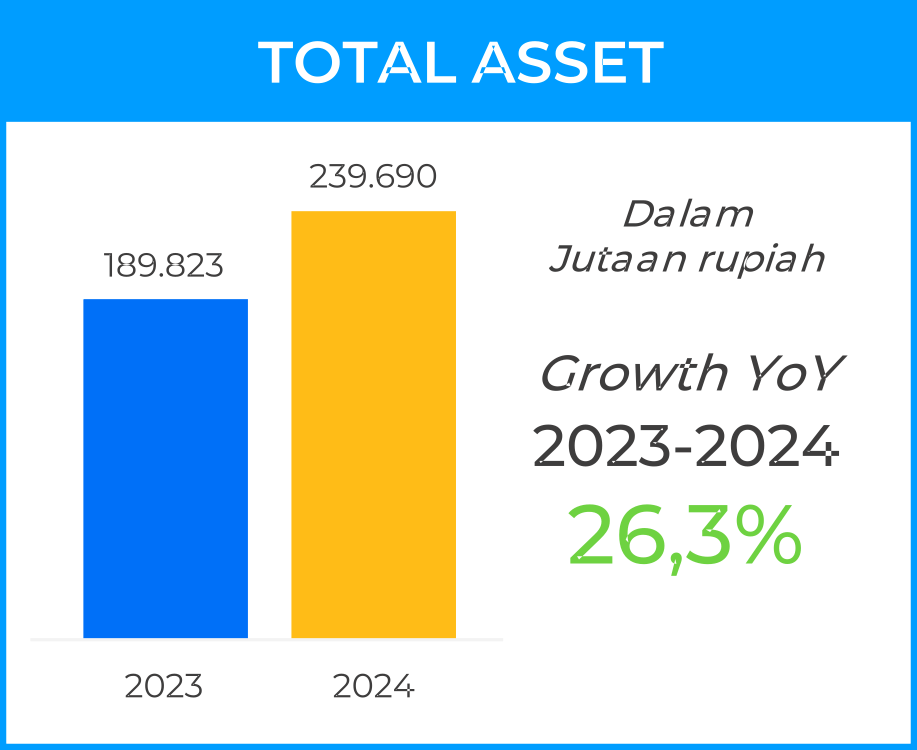

Laporan Posisi Keuangan

| Laporan Posisi Keuangan | 2024 | 2023 |

|---|---|---|

| Total Aset | 239.959 | 189.822 |

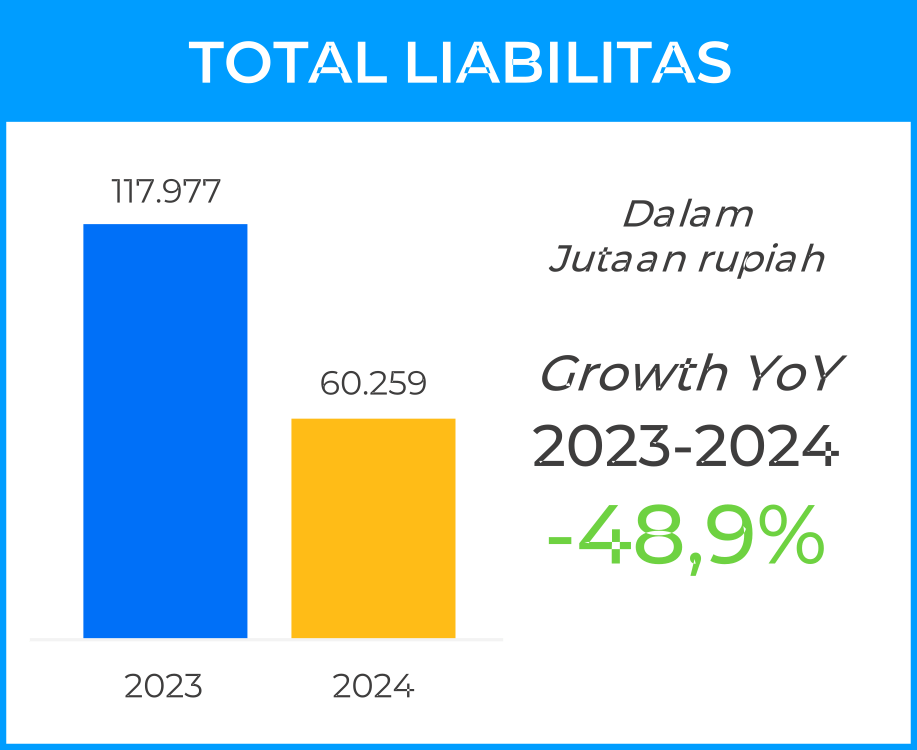

| Total Liabilitas | 60.434 | 117.977 |

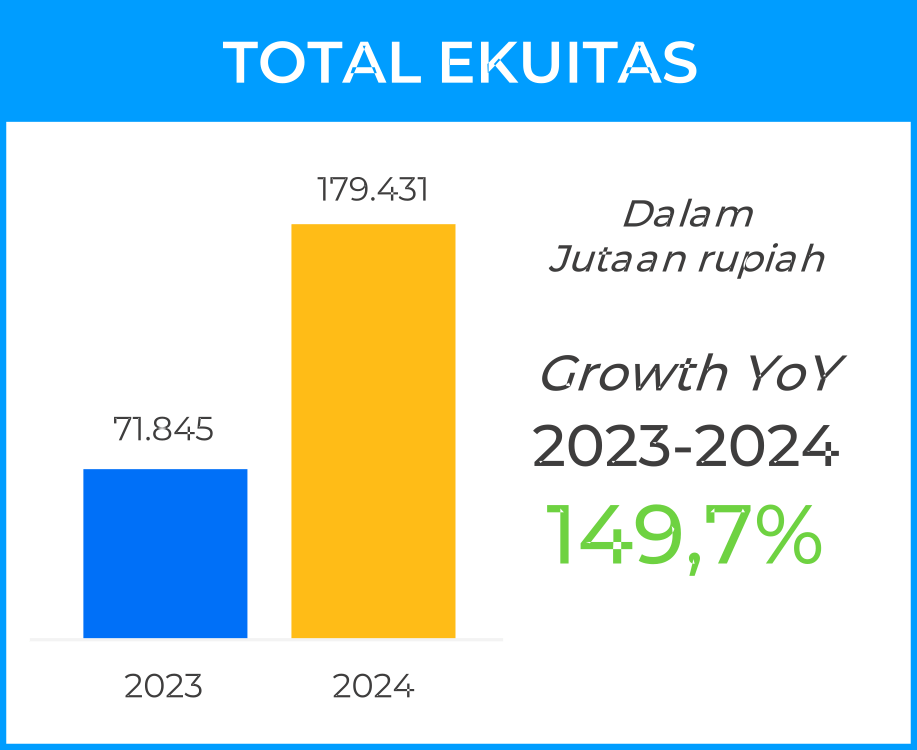

| Total Ekuitas | 179.524 | 71.845 |

Rasio Keuangan (%)

| Rasio Keuangan (%) | 2024 | 2023 |

|---|---|---|

| ROA (%) | 13 | 7 |

| ROE (%) | 17 | 18 |

| NPM (%) | 15 | 11 |

| DER (x) | 0.34 | 1.64 |

| DAR (x) | 0.25 | 0.62 |

Grafik Ikhtisar Data Keuangan Penting

Ringkasan Risalah RUPST Tahun Buku 2024

Pemanggilan Rapat Umum Pemegang Saham Tahunan PT Adiwarna Anugerah Abadi Tbk Tahun Buku 2024

Pengumuman Rapat Umum Pemegang Saham Tahunan PT Adiwarna Anugerah Abadi Tbk Tahun Buku 2024

Produk & Sistem Proteksi Kebakaran Kami

Control Valves

- Butterfly Valve

- Gate Valve

- Check Valve

- Y Strainer

- Ventilasi Udara Otomatis

Pompa Kebakaran

- Split Case Horisontal

- End Suction

- Turbin Vertikal

- Hydrostream

Sistem Foam

- Konsentrat Busa

- Tangki Penyimpanan Busa

- Ruang Busa

- Monitor Air Busa

- Busa Ekspansi Tinggi

Sistem Pencegah Kebakaran

- Sistem Inergen

- Sistem FM-200

- Sistem Novec 1230

- Sistem CO₂ Tekanan Tinggi

Sistem Alarm Kebakaran

- Panel Kontrol Addressable

- Detektor

- Bel Alarm

- Annunciator

- Intelligent & IP Based

Hidran & Sprinkler

- Sistem Penyiram Kebakaran

- Sistem Hidran Kebakaran

- Peralatan Pemadam Kebakaran

- Sistem Semprotan Air

- Sistem Banjir