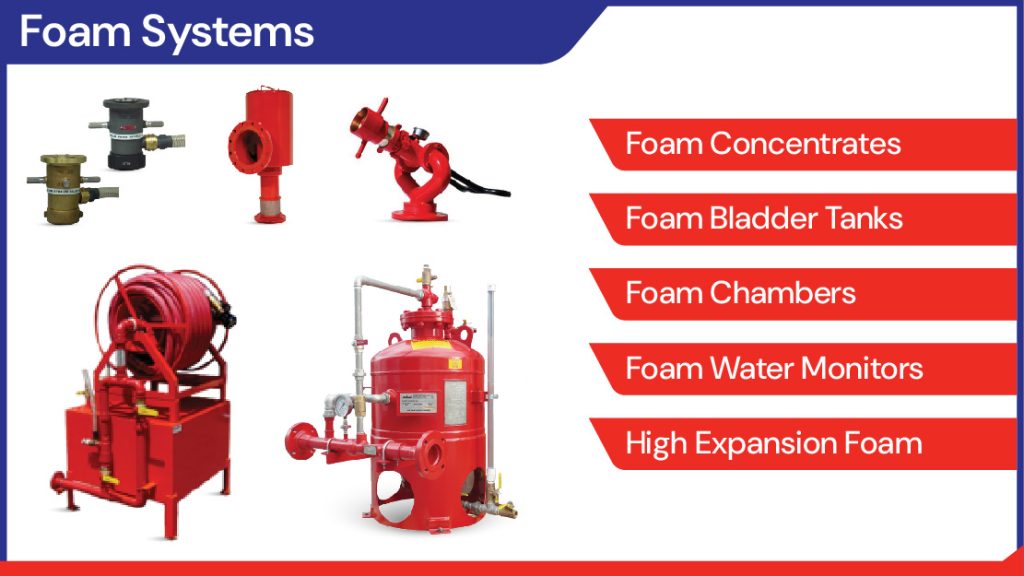

Foam systems in fire suppression systems are commonly installed in industrial areas with Class B fire risks, such as fires caused by flammable liquids like gasoline, oil, thinner, and paint. Unlike fire hydrants that use pressurized water, foam fire fighting systems are the most effective solution for liquid-based fires. Since water and oil do not mix, using water on flammable liquids can spread the fire, making it more dangerous.

A foam fire suppression system works by covering flammable liquids, cutting off essential fire elements like air and heat. The foam fire sprinkler system and foam nozzle fire fighting components ensure rapid and effective fire control. Additionally, fire fighting foam is designed to smother flames, while the foam inductor fire fighting mechanism optimizes foam distribution. The foam fire fighting system is the best choice for industrial and oil-related fire hazards, providing enhanced safety and fire prevention.

Foam Concentrates

Specification

- Appearance : Clear Light Yellow

- Specific Gravity : 1.02 +/- 0.01

- pH : 7.8 +/- 0.5

- Viscosity : 3.0 cps maximum

- Approval : UL Listed

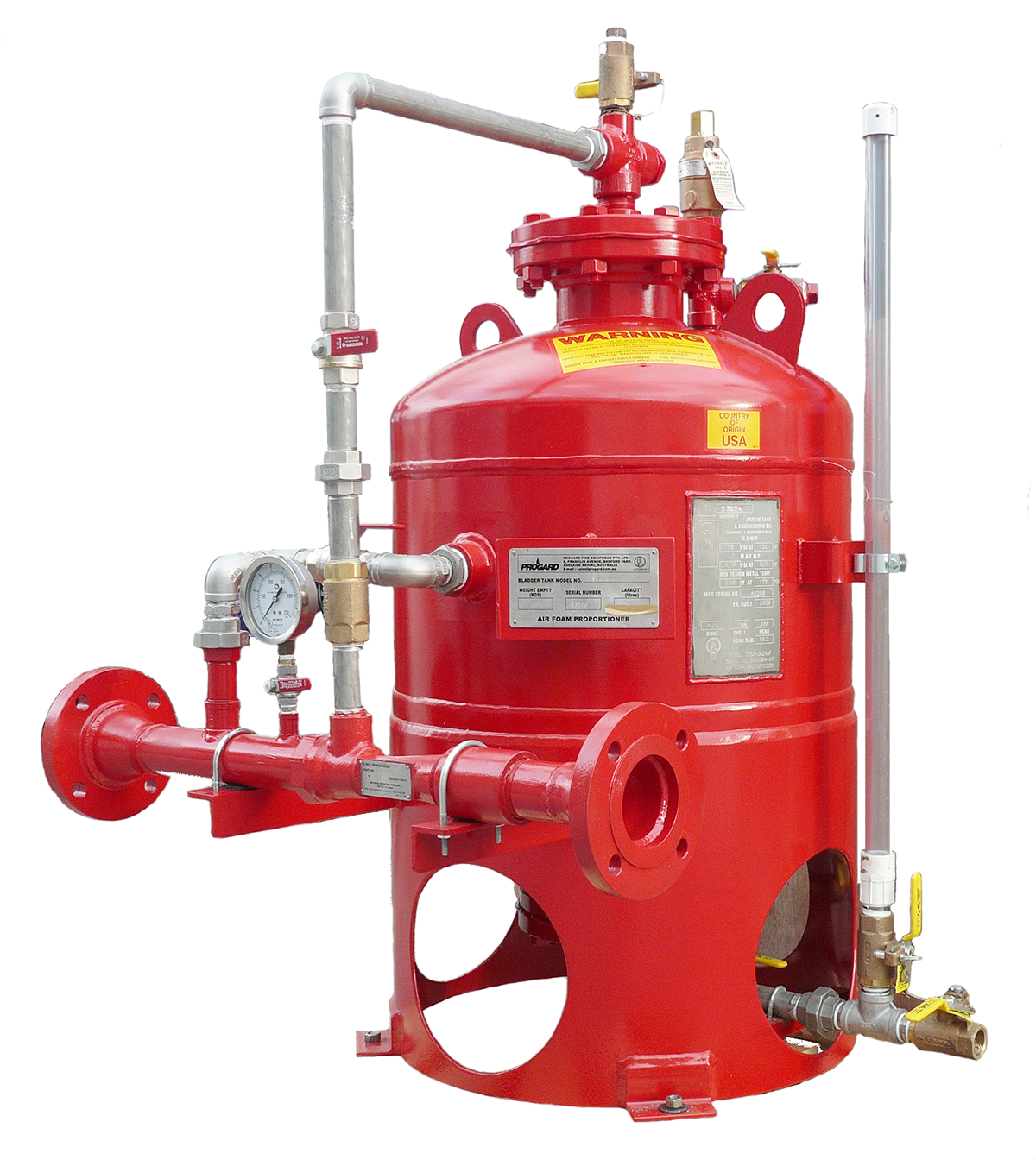

Foam Bladder Tanks

Specification

- Tank Capacity : 113 or 227 litres (30 or 60 gallons)

- Tank Material : Stainless steel 316 SS (or 304 SS)

- Hose Reel Type : Continuous flow, rim rewind

- Reel Material : Mild steel (or stainless steel 316SS)

- Booster Hose : 1 1⁄2″ diameter x 30 metres length. Red colour. Non-collapsible, textile, braided reinforcement, 13.8 bar (or higher).

- Prepiped Eductor : 227 lpm or 360 lpm (60 or 95 gpm)

- Eductor Model : 02 PE95-B

- Eductor Material : Brass

- Nozzle Model : 04 HNCG-330B (brass) or 04 HNCG-330A (aluminium alloy)

- Nozzle Type : Non air-aspirating, fog/ss pattern.

- Shutoff Valve Type : Ball, full bore, 1 1⁄2” threads Valve Material : Brass

Foam Chambers

Specification

- Defined by NFPA 11 as Type II foam discharge outlet for delivering foam to the surface of a flammable liquid

- Unique Chamber design allows for Field Testing without removal of vapour seal assembly

- Bolted Inspection Access to Interior of Chamber

- Minimum working pressure is 2.8 bar (40 psi) Maximum working pressure is 7 bar (100 psi)

- Frangible Glass Vapour Seal breaks at pressures between 0.7 to 1.75 bar. Maximum permissible back pressure on seal is 0.06 bar

- Chamber is manufactured in Carbon Steel with a #304 StainlessSteel Screen covering the foam air intakes

- Tie-in connection are standard ANSI B16.5 Class 150# FF flanges

- Choice of Solid or Spilt Deflector Stainless Steel Orifice (calculated to flow predetermined foam solution at pressure available to the flanged inlet of chamber)

Foam Water Monitors

Specification

- Construction : Brass

- Waterway : Dual 2.5”

- Maximum Flow : 750 GPM (2,840 lpm)

- Horizontal Movement : 360º

- Vertical Elevation : 130º

- Vertical Travel Operation : Handle Lever

- Base Inlet : 3” or 4” ANSI 150# FF flange

- Discharge Tip : 2½” male NHT

- Finish : Red Paint Approval : FM approved

Fire Hose Reel

Specification

- Tank Capacity : 113 or 227 litres (30 or 60 gallons)

- Tank Material : Stainless steel 316 SS (or 304 SS)

- Hose Reel Type : Continuous flow, rim rewind

- Reel Material : Mild steel (or stainless steel 316SS)

- Booster Hose : 1 1⁄2″ diameter x 30 metres length. Red colour. Non-collapsible, textile braided reinforcement, 13.8 bar (or higher).

- Prepiped Eductor : 227 lpm or 360 lpm (60 or 95 gpm)

- Eductor Model : 02 PE95-B

- Eductor Material : Brass

- Nozzle Model : 04 HNCG-330B (brass) or 04 HNCG-330A (aluminium alloy)

- Nozzle Type : Non air-aspirating, fog/ss pattern.

- Shutoff Valve Type : Ball, full bore, 1 1⁄2” threads Valve Material : Brass